Revolutionizing Manufacturing Industries: The Power of Manufacturing ERP with Low-Code Hybrid Blockchain

In modern industries, Manufacturing Enterprise Resource Planning (ERP) systems play a crucial role in streamlining operations, improving efficiency, and driving growth. This article explores the transformative potential of combining Manufacturing ERP with Low-Code Hybrid Blockchain technology, which can further revolutionize manufacturing industries by enhancing transparency, efficiency, and security.

Low-Code Hybrid Blockchain technology, a powerful combination of Low-Code development platforms and Blockchain, offers a unique approach to building and deploying applications rapidly. It provides the benefits of simplified development, increased flexibility, and the immutability and decentralized nature of Blockchain.

Understanding Manufacturing ERP

Manufacturing ERP systems are comprehensive software solutions designed specifically for manufacturing industries. These systems integrate various business functions, including inventory management, production planning, supply chain management, quality control, and reporting. Key features of Manufacturing ERP systems include real-time data integration, process automation, and centralized data management.

Implementing Manufacturing ERP brings numerous benefits to manufacturing industries, such as improved operational efficiency, better inventory management, enhanced decision-making, and increased productivity. These systems provide a holistic view of the entire manufacturing process, enabling organizations to optimize their operations and respond quickly to market demands.

Exploring Low-Code Development

Low-Code development is an approach that enables rapid application development with minimal coding. Low-Code platforms provide visual interfaces, pre-built components, and drag-and-drop functionalities, allowing developers to build applications quickly and easily. This approach reduces the reliance on traditional hand-coding, enabling faster development cycles and greater agility.

Advantages of using Low-Code platforms in manufacturing ERP systems include accelerated development and deployment, improved collaboration between IT and business teams, reduced development costs, and the ability to quickly adapt to changing business requirements. Low-Code development empowers organizations to build custom solutions that align with their specific needs and processes.

Unleashing the Potential of Blockchain in Manufacturing

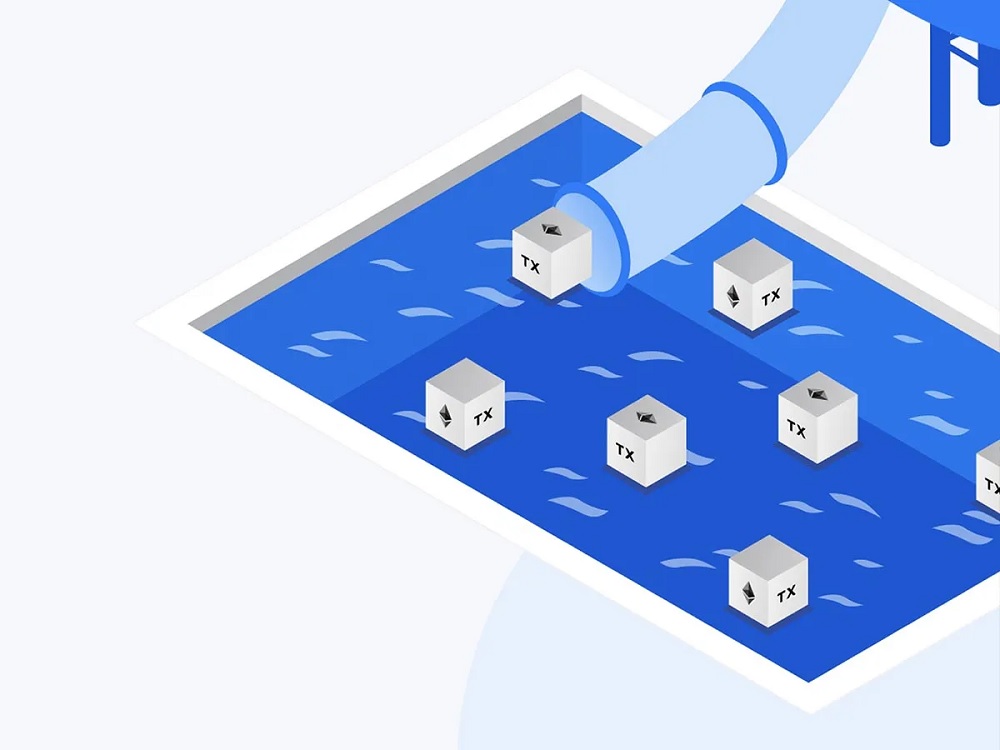

Blockchain technology, known for its decentralized and transparent nature, has the potential to transform manufacturing industries. Blockchain provides an immutable and auditable ledger that securely records transactions and data across a network of participants. Its applications in manufacturing include supply chain management, product traceability, quality control, and warranty management.

Implementing Blockchain in Manufacturing ERP systems brings several benefits, such as enhanced transparency, improved trust between stakeholders, increased supply chain efficiency, and reduced fraud and counterfeiting. Blockchain enables end-to-end visibility, enabling manufacturers to track and verify the authenticity and origin of products, ensure compliance with regulations, and create trusted networks with suppliers and customers.

The Synergy of Low-Code and Blockchain in Manufacturing ERP

The integration of Low-Code development and Blockchain in Manufacturing ERP systems creates a powerful synergy that enhances efficiency and transparency in manufacturing processes. Low-Code development simplifies the development and integration of Blockchain functionality, enabling manufacturers to quickly implement Blockchain solutions without extensive coding expertise.

This combination allows for the rapid development of custom applications that leverage Blockchain technology to optimize manufacturing operations. Manufacturers can implement smart contracts for automating supply chain processes, create decentralized ledgers for tracking and verifying product information, and develop Blockchain-based solutions for quality control and compliance management.

Key Features and Functionalities of Manufacturing ERP with Low-Code Hybrid Blockchain

Real-time inventory management and tracking: Manufacturing ERP with Low-Code Hybrid Blockchain enables real-time visibility into inventory levels, locations, and movements, ensuring accurate inventory management and reducing stockouts and overstocking.

Streamlined supply chain management: The integration of Low-Code and Blockchain simplifies supply chain management by enabling transparent and automated processes, optimizing procurement, order fulfillment, and logistics.

Enhanced quality control and compliance: Manufacturers can leverage Low-Code Hybrid Blockchain to implement robust quality control mechanisms, trace ability, and compliance management. Blockchain ensures the immutability of quality control records and enables real-time tracking of product information, ensuring adherence to regulations and standards.

Efficient production planning and scheduling: Low-Code Hybrid Blockchain empowers manufacturers to optimize production planning and scheduling by leveraging real-time data from the Blockchain. This enables better resource allocation, reduced lead times, and improved production efficiency.

Seamless integration with other business systems: Manufacturing ERP with Low-Code Hybrid Blockchain can easily integrate with existing business systems, such as CRM, finance, and HR. This facilitates smooth data flow and enhances overall operational efficiency.

Automated reporting and analytics: With the integration of Low-Code development, manufacturers can leverage the power of automation in generating real-time reports and analytics. This provides valuable insights into production performance, quality metrics, and supply chain analytics, enabling data-driven decision-making.

Overcoming Challenges in Implementing Manufacturing ERP with Low-Code Hybrid Blockchain

While the combination of Manufacturing ERP, Low-Code development, and Blockchain offers significant benefits, there are challenges to consider. Some potential challenges include:

Integration complexity: Integrating Low-Code development and Blockchain with existing ERP systems can be complex and require careful planning and execution.

Skillset requirements: Implementing Low-Code Hybrid Blockchain may require skilled resources with expertise in both Low-Code development and Blockchain technologies.

Data interoperability: Ensuring seamless data flow between different systems and platforms can be challenging when integrating Manufacturing ERP with Low-Code Hybrid Blockchain.

To mitigate these challenges, organizations can adopt the following strategies:

Conduct thorough planning and feasibility studies before implementation.

Engage experienced consultants or service providers who specialize in Manufacturing ERP, Low-Code development, and Blockchain.

Provide training and upskilling opportunities for the IT team to acquire the necessary skills.

Collaborate closely with stakeholders and end-users to ensure their buy-in and involvement throughout the implementation process.

Best Practices for Implementing Manufacturing ERP with Low-Code Hybrid Blockchain

To ensure successful adoption of Manufacturing ERP with Low-Code Hybrid Blockchain, organizations should follow these best practices:

Establish clear objectives and requirements: Define the goals and requirements of the implementation, considering the specific needs of the manufacturing industry and the desired outcomes.

Engage key stakeholders and involve end-users in the process: Collaborate with key stakeholders, including management, IT teams, and end-users, to gain a comprehensive understanding of the business processes and align the implementation accordingly.

Conduct thorough testing and training: Prioritize comprehensive testing to identify and resolve any issues or bugs before the system goes live. Additionally, provide thorough training to end-users to ensure they are equipped with the necessary knowledge and skills to effectively use the Manufacturing ERP with Low-Code Hybrid Blockchain system.

Plan for scalability and future growth: Consider the scalability of the system to accommodate future growth and evolving business needs. Ensure that the chosen Low-Code and Blockchain solutions can easily adapt and scale as the organization expands.

Security and Data Privacy Considerations in Manufacturing ERP with Low-Code Hybrid Blockchain

Implementing Manufacturing ERP with Low-Code Hybrid Blockchain requires careful attention to security and data privacy considerations. Some key considerations include:

Ensuring data integrity and confidentiality: Implement robust security measures to protect sensitive data stored within the Manufacturing ERP system and the Blockchain. This includes encryption, access controls, and regular security audits.

Implementing robust security measures in the system: Follow best practices for securing the Low-Code development platform, the Blockchain network, and the underlying infrastructure. This includes implementing authentication mechanisms, securing APIs, and conducting regular vulnerability assessments.

Compliance with data protection regulations: Adhere to applicable data protection regulations, such as the General Data Protection Regulation (GDPR) or industry-specific compliance requirements. Ensure that personal and sensitive data is handled and stored in compliance with these regulations.

Future Trends and Innovations in Manufacturing ERP with Low-Code Hybrid Blockchain

The future of Manufacturing ERP with Low-Code Hybrid Blockchain holds exciting possibilities. Some emerging trends and innovations include:

AI and machine learning integration in manufacturing ERP systems: By integrating AI and machine learning algorithms, Manufacturing ERP systems can provide predictive analytics, anomaly detection, and intelligent automation, further enhancing operational efficiency and decision-making.

Evolution of Blockchain technology in supply chain management: Blockchain technology is continuously evolving to address the specific challenges of supply chain management. Innovations such as smart contracts, Internet of Things (IoT) integration, and decentralized marketplaces hold promise for revolutionizing supply chain processes.

Advances in Low-Code development for manufacturing industries: Low-Code development platforms are evolving to provide more industry-specific features and templates tailored to the unique needs of manufacturing industries. This will further accelerate the development and deployment of custom Manufacturing ERP solutions.

The combination of Manufacturing ERP, Low-Code development, and Blockchain technology presents a transformative solution for manufacturing industries. By leveraging the benefits of Manufacturing ERP systems, the agility of Low-Code development, and the transparency of Blockchain, organizations can streamline operations, enhance efficiency, and ensure trust and security in their manufacturing processes.

Implementing Manufacturing ERP with Low-Code Hybrid Blockchain requires careful planning, stakeholder engagement, and adherence to best practices. However, the benefits in terms of real-time visibility, optimized processes, improved quality control, and enhanced compliance make it a powerful solution worth embracing.

Manufacturing industries are encouraged to explore the potential of Manufacturing ERP with Low-Code Hybrid Blockchain and leverage this revolutionary technology to gain a competitive edge in the evolving digital landscape. By embracing this powerful solution, manufacturers can unlock new opportunities for growth, efficiency, and innovation in the manufacturing sector.